Influence of magnesia on iron ore sinter properties .

Iron ore Þnes, limestone, ... behaviour of dolomite in iron ore sintering is ... et al. Influence of magnesia on iron ore sinter properties and productivity ...

WhatsApp)

WhatsApp)

Iron ore Þnes, limestone, ... behaviour of dolomite in iron ore sintering is ... et al. Influence of magnesia on iron ore sinter properties and productivity ...

How it works: The Blast Furnace The Potteries. At the same time the iron oxides are going through these purifying reactions, they are also beginning to soften then ...

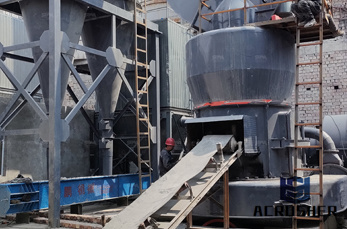

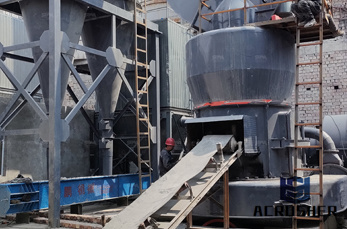

Sinter plants agglomerate iron ore ... is still produced using the sinter plant–blast furnace ... are fed to sintering machine and burnt therein to ...

The raw materials used to produce pig iron in a blast furnace are iron ore, coke, sinter, and limestone. Iron ores are mainly iron oxides and include magnetite, hematite, limonite, and many other rocks. The iron content of these ores .

1990 Fundamental study of pore formation in iron ore sinter and pellets ... In addition to iron ore, limestone, dolomite, ...

Recent advances in iron ore sintering ... ventional sintering process, the blended ore, limestone and burnt lime are first mixed and pelletised in the HPS

iron ore sintering limestone Newest Crusher, Grinding . Limestone, coke and sinter Raw materials for steelmaking Limestone, coke and sinter raw materials for ...

Iron ore sintering; woody pellets, biomass char; coke breeze, CO 2 emissions Introduction ... ( iron ore, return sinter, limestone and water) are kept constant.

Iron Ores and Concentrates At Extaca ... limestone, hydrated ... Fig. lFlowsheet of the Extaca plant for sintering iron ore fines and taconite concentrates.

Home > Stone > how is limestone ore processed. how is limestone ore processed. Limestone Wikipedia, the free encyclopedia. ... What Is Iron Ore Sintering? (with ...

supplementary fuel in the iron ore sintering process. Coke ... The raw materials used in this work are iron ore fines, limestone, coke breeze and blast

MATHEMATICAL MODELLING AND OPTIMISATION OF ... The main aim of iron ore sintering is to produce a strong and reducible ... fluxes were limestone, magnesite, ...

Making iron Roll over the dots to see the names What do we need to make iron? Iron is usually made from iron ore, coal and limestone

The raw materials used to produce pig iron in a blast furnace are iron ore, coke, sinter, and limestone. Iron ores are mainly iron oxides and ... and sintering.

On Jun 1, 2010 T. Umadevi (and others) published: Influence of limestone particle size on iron ore sinter properties and productivity

Phase Formation in Iron Ore Sintering . ... During the iron ore sintering process, iron ore fines (< 6 mm) are mixed with limestone flux

Carbon(C) Limestone (CaCO3) Preheated air ... iron ore sintering process which ... "Simulation of sintering of iron ore packed" is the property of ...

IRON ORE SCENARIO IN ... high grade ores have led to a very strong demand for both pelletising and sintering of iron ores. ... binders like limestone ...

Iron ore fluxed sinter is the main ferrous burden of Jindal south west steel limited (JSWSL) blast furnaces. In sinter plant fluxes including limestone and dolomite ...

The raw materials needed limestone, coke, air and iron ore and the chemistry of ... iron ore sintering limestone; use of limestone in iron extraction; ...

The sintering mixture, necessary for iron ore sinter production, ... – dolomite and limestone was determined by calculation for particular charges.

ticles of iron ore, limestone, ... iron ore sintering bed model which takes the single particle into consideration and incorporates more informa

Simulation of sintering of iron ore bed with variable ... Phoenics Figure 1 presents schematically an iron ore sintering process. ... and limestone are mixed and ...

limestone, dolomite, ... Iron ore sintering creates substantial offgas volumes, and treating these in order to meet increasingly stringent environmental standards

WhatsApp)

WhatsApp)